Compressed air is a powerful tool for many different applications in the food and beverage industry. Consider a hypothetical manufacturing facility that uses compressed air to make yogurt. In one area of the factory, compressed air forces flavor the powder through pipes to mix with plain yogurt. In another area, compressed air supplies oxygen to yogurt during cultivation. As soon as curd cultivation is finished, it is filled in further processes into containers cleaned with compressed air. During this automatic process, the valves and actuators also open to fill and remove the air.

Milestone Pneumatics offers a wide variety of high-quality Air Compressors. Milestone Pneumatics is a distributor of the ELGi brand of lubricated and oil-free reciprocating compressors, ELGi lubricated rotary screw compressors and compressed air accessories and spares. We also provide strong service support for all of our products.

The importance of using air compressors in food and beverage processing applications cannot be underestimated. Several stages of the manufacturing process benefit from the use of compressed air, such as:

- Mixing food

- Packaging Movement

- Pumping Fluids

- Air Filtration

This final stage is arguably the most important role air compressors play in the food and beverage industry. Filtering contaminated air is essential to producing clean food products, helping you protect your customers’ health and avoid liability.

For this reason, air compressors used in food manufacturing environments must meet the highest standards. For example, if your processes feed contaminated air into a ready-to-eat package, the dirt or bacteria in that air pass directly to your customer. This creates a risk not only for them but also for your company.

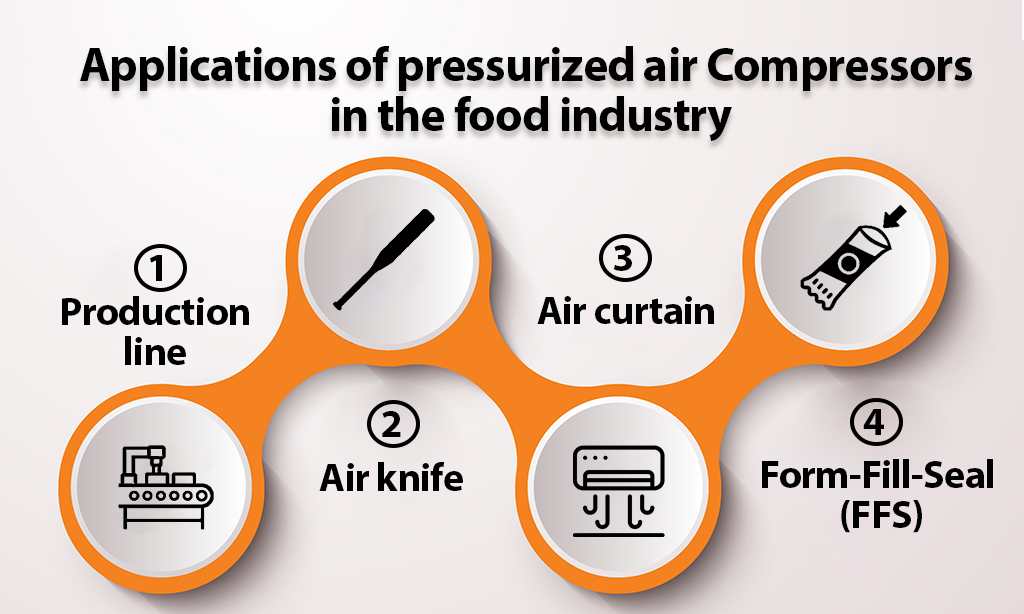

Applications of pressurized Air Compressors in the food industry:

Production line

Sorting uses compressed air to separate the material by weight. And in making yogurt, the air forces the flavors to mix with the unprocessed yogurt. It also provides oxygen for the product while the yogurt is being cultured. Compressed air also helps push the filling into pie crusts and other filled baked goods.

Air knife

In a production line, high-velocity compressed air flowing through an air sieve is used to cool products, for quick drying after rinsing or rinsing water from products (bottles, cans or vegetables). It is used to remove crumbs and excess sugar from baked goods. Avoid products that are burnt to avoid damage, dry products before inkjet labeling, remove water or particles from product surfaces before packaging, before cutting and peeling fruits and vegetables.

Air curtain

Compressed air-powered air curtains are fitted over doors to separate two spaces with different environments, preventing the flow of outside air and inside air while allowing traffic to flow freely. block the outflow. Air curtains promote a clean environment by preventing insects and other pollutants from entering your facility. The constant opening and closing of doors put a strain on your heating or cooling system and increases your energy costs. With an efficient air curtain, you significantly reduce heat loss and unwanted cold air from the door.

Form-Fill-Seal (FFS)

High purity air is critical in generating compressed air for all applications, especially form-fill-seal packaging systems. The air should be free of pollutants due to direct contact with packaged food. The pneumatic system is the preferred system over hydraulics because of the potential for oil leakage in hydraulics.

These are some of the uses of compressed air for the food and beverage industry. Call us at Milestone Pneumatics now and learn about other uses of this valuable utility. Receive a free air compressor Quote at ccs@milestonepneumatics.com