One well-known type of compressor from the positive displacement compressor category is the reciprocating compressor. When compressing air or gas, a reciprocating component such as a piston or plunger is used.

The most typical applications for reciprocating air compressors demand high gas pressure and modest flow rates. The reciprocating compressors are typically used to fill the tyres of vehicles, for small paint jobs, for business needs, for dust cleaning, and for hand tools, among other things.

How Does a Reciprocating Compressor Work?

The reciprocating compressor’s design is comparable to that of your automobile or motorcycle’s engine. In a reciprocating compressor, the capacity of the cylinder is inversely correlated to the absolute temperature of the gas at the inlet valve. The volume that enters the cylinder increases with the temperature of the gas.

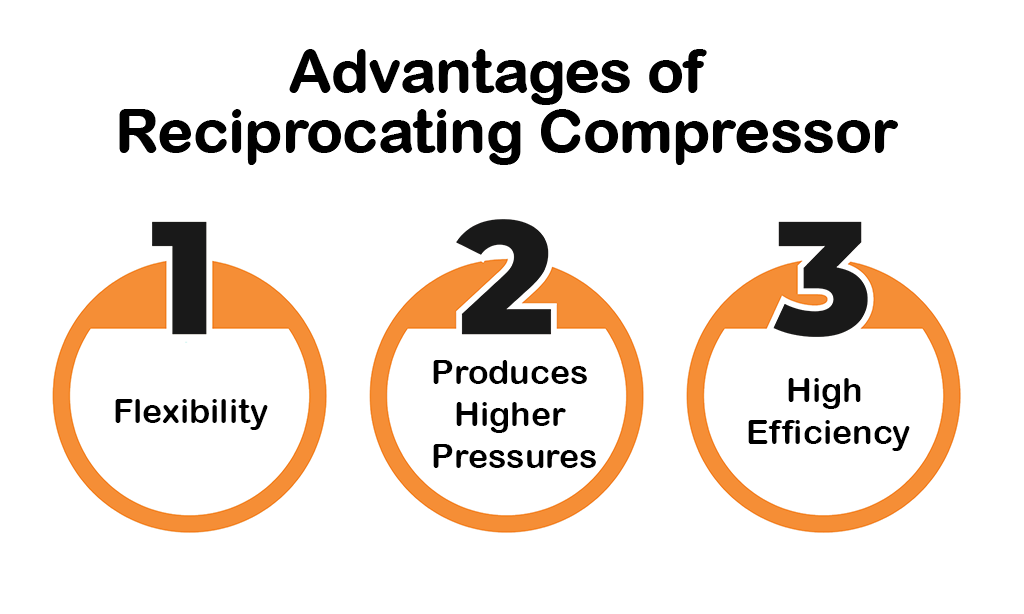

Advantages of Reciprocating Compressor

The use of reciprocating air compressors has three key benefits. These benefits include the ability to operate the device in a variety of ways, higher pressure generation, high efficiencies attained, and the effectiveness of intermittent cycling.

- Flexibility

This kind of air compressor is available both oil-flooded and oil-free. As a result, you are no longer constrained by the problem of oil contamination if you chose a reciprocating compressor for your application.

- Produces Higher Pressures

Reciprocating compressors have a greater pressure range than rotary screw compressors do. In fact, pressures can reach as high as 30,000 PSI. They are, however, also appropriate for temperature control applications requiring 60 to 90 PSI.

- High Efficiency

Higher pressures can be generated by reciprocating compressors, and their operation requires less energy. This makes this particular type of compressor very advantageous in situations where high pressure intermittent use is required.

Disadvantages of Reciprocating Compressor

In industrial and commercial applications, reciprocating compressors are still in demand. However, they have also earned a bad reputation for a few flaws. Although reciprocating compressors of today are much more efficient and dependable than those of the past, it is crucial to understand their limitations.

- Mechanical Wear and Tear

Even when the machine is kept at the proper levels of lubrication, the compressing motion of the piston results in inevitable wear. Modern reciprocating compressors’ lifespans have been increased by engineers by modifying the pistons’ metal alloys and making them more lightweight as a whole.

- Vibration

A reciprocating compressor’s main risk is vibration. Another inevitable result of compression action, it must be kept within tolerances to limit any damage.

- Noise

The reciprocating compressor’s piston action is naturally louder than that of the screw or centrifugal compressors. As a result, there are fewer locations where you might be able to put up your compressor.

Conclusion

Reciprocating compressors are incredibly useful, flexible, and affordable. Both commercial workshops and factories, as well as your own garage, can benefit greatly from them. Milestone Pneumatics is the leading reciprocating compressor seller in gujarat. For more information kindly email at ccs@milestonepneumatics.com