When evaluating the proper use of compressed air systems and storage, many people misunderstand control storage. Many people refer to control storage as VAT or primary storage. However, the term control storage control refers to the main function of the compressor to maximize performance.

For the purpose of this post, we will define this type of storage as any storage created prior to air compressor discharge and any cleaning equipment. These appliances include filters and air dryers. Milestone Pneumatics is the leading supplier of reciprocating air compressors in Ahmedabad, Gujarat.

Control storage differs from on-demand storage in a special way. On-demand storage is made after cleaning equipment and before demand regulation. Basically, storage types differ in storage space and usage. It is not uncommon to use both types of storage in compressed air system design.

Why is Control Storage Used in Reciprocating Air Compressors?

Reciprocating air compressors were once the preferred air compressor and were widely used in industrial plants. Control storage has always been an essential part of using an air compressor, regardless of the size of the system.

- The compressor lowers the heart rate by discharge.

- Contributed to the removal of condensate by condensation and settlement.

- Eliminate short cycling of compressor controls.

When rotary screw compressors began to appear on the market in 1960, the reproduced air compressor was almost completely replaced. The death of the market for reintroducing compressors created confusion over when and how to implement control storage.

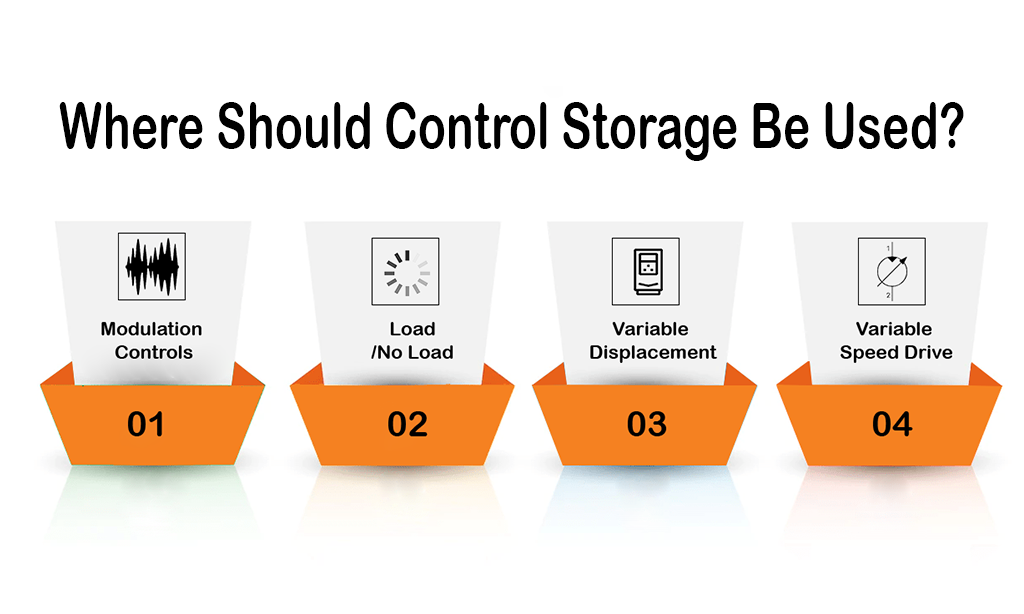

Where Should Control Storage Be Used?

There are a few principles that can be used to help determine whether you need to use control storage. These principles are based on the four basic types of compressor controls on rotary screw air compressors.

Modulation Controls

Rotary screw compressors with modulation control do not require control storage. While modulation control is not the most efficient control over partial compressor load, its simple control to changes in compressor load reduces the need for feedback storage.

Load/No Load

Load/no load (also known as on-line/off-line) control requires control storage. Without the right amount of control storage, there will be little cycling of the controls. The result is premature wear and failure of the compressor control system.

Variable Displacement

Variable displacement control is similar to modulation in the fact that control storage is not necessary as long as the plant load remains within the operating range of this type of control.

Variable Speed Drive

Variable speed drives are the same for both control modulation and variable displacement because control storage offers little benefit as long as compressor operation is within the operating range of the VSD. As in the case of variable displacement control.

Summary

Control storage is a tool that can greatly improve the reliability and performance of an air compressor system but needs to be properly evaluated. Use the tips above to help you decide whether this storage option is right for you. As always, if you have any questions regarding control storage, please contact us at Milestone Pneumatics.