Reciprocating air compressors also known as piston air compressors are among the earliest types of air compressors. They come in single-acting and double-acting varieties, and they can be either oil-lubricated or oil-free.

A piston operates a reciprocating compressor by compressing and displacing air inside a cylinder to increase pressure. The pressure ranges that reciprocating compressors can reach can be single- or multi-stage variations.

The Characteristics of Reciprocating Air Compressors:

Since reciprocating air compressor technology is one of the most affordable, simple, and popular, it has a number of benefits, such as:

- Support and maintenance are easily available.

- Availability of replacement parts.

- Reasonably priced spare parts.

- Relies on operating mechanisms that are less complex.

- Comes in several sizes.

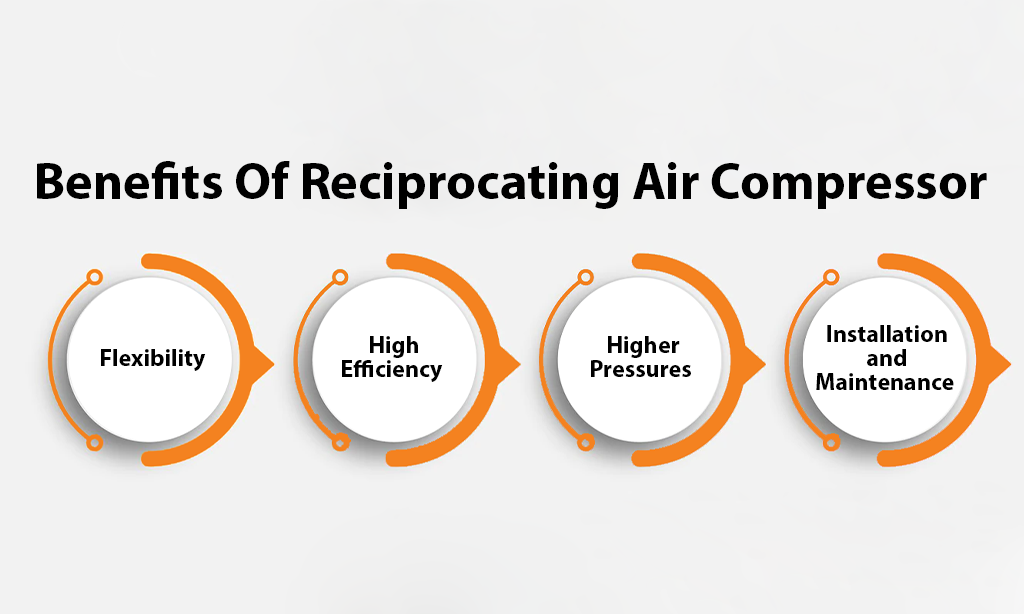

Benefits Of Reciprocating Air Compressor:

These compressors are utilized in a wide range of industrial applications and for a wide range of purposes. Every workplace, including auto shops, chemical factories, oil refineries, agricultural facilities, facilities for processing natural gas, refrigeration technology facilities uses reciprocating air compressors.

Flexibility

The manufacturers of reciprocating air compressors provide both lubricant- and oil-free models. Additionally, to lessen positioning constraints, it can be tank mounted or base mounted. Regarding functionality, design, and extra features for any industrial application, there are many options accessible on the air compressors market.

High Efficiency

Higher pressures can be produced by reciprocating compressors while requiring less energy to operate. This makes this sort of compressor extremely beneficial for more extensive applications requiring sporadic high pressure utilisation. Reciprocal compressors main features are conventional, straightforward electrical controls and mechanical parts.

Higher Pressures

The heavy-duty components and powerful motors used in air compressors allow them to operate at higher pressure levels. In comparison to rotary screw types, reciprocating types are able to generate higher pressures.

Installation and Maintenance

Suppliers of air compressors frequently offer installation and maintenance packages that involve changing the appropriate parts required to keep the compressor in peak operating condition.

Summary:

Most companies, including those in the food and beverage, automotive, power generation, and other manufacturing industries, choose air compressors as their primary manufacturing tool. The driving force behind it is productivity and mechanisation.

Consider the above factors before making a final decision if you plan to purchase a reciprocating compressor from the Milestone Pneumatics reputable seller.