The air compressor converts normal air into compressed and high-pressure air for a variety of uses under the three categories of consumer, commercial and industrial. You have decided that your current application needs compressed air. You will understand how much air you need, how the compressor will run and which engine to use to power it. Now is the time to decide which air compressor is best for your needs.

All air compressors will have any of these three phases, and all air compressors will eventually deliver high-pressure air flows in a controlled flow or in 24/7 industrial applications.

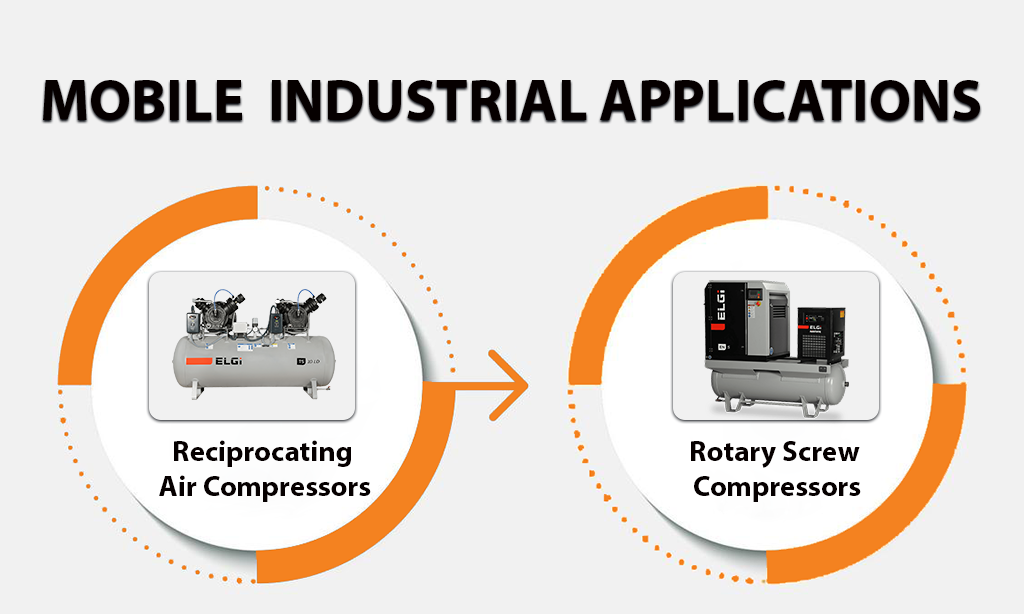

There are 2 types of air compressors used in mobile industrial applications:

- Reciprocating Air Compressors

- Rotary Screw Compressors

Each of these air compressors has its own unique advantages and challenges, which we will break down in this article.

Reciprocating Air Compressors:

Reciprocating compressors are the most common air compressors found in mobile applications and are the type most people are familiar with. There is a wide variety of manufacturers and distributors around the world, offering many options.

Benefits:

Reciprocating air compressors usually have the lowest initial purchase price. They are ideal for low-duty cycling activities. Unlike many wine and screw compressors, most reciprocating compressors can be serviced or remodeled in the field with simple hand tools.

Rotary Screw Compressors:

Traditionally, rotary screw compressors have been found in stationary applications and not widely in mobile applications. However, times have changed! Rotary screw compressors are more affordable and their advantages are widely recognized in various industries. Today, the rotary screw air compressor is used in many industrial applications and is manufactured by companies around the world, including VMAC.

Benefits:

Rotary screw compressors are known for their compact size, longevity and high airflow. The high-duty bicycle application is best suited for a rotary screw compressor because it is designed to run 100% of the time. Generally, a screw compressor does not require an air receiver tank for operation. Compared to other compressor types, rotary screw air compressors have less wear, and repairs usually involve filter and oil replacement.

Conclusion:

Milestone Pneumatics is the leading air compressors supplier and dealer in Gujarat. Industry Experts Explore Useful Tips and Interesting Facts About Compressed Air Systems. Our blog has energy efficiency tips and answers to all your questions. For more details contact us at 079-29683107 / +91 99048 05712 or Visit www.milestonepneumatics.com